RING TYPE JOINT (RTJ) GASKETS

TYPES :

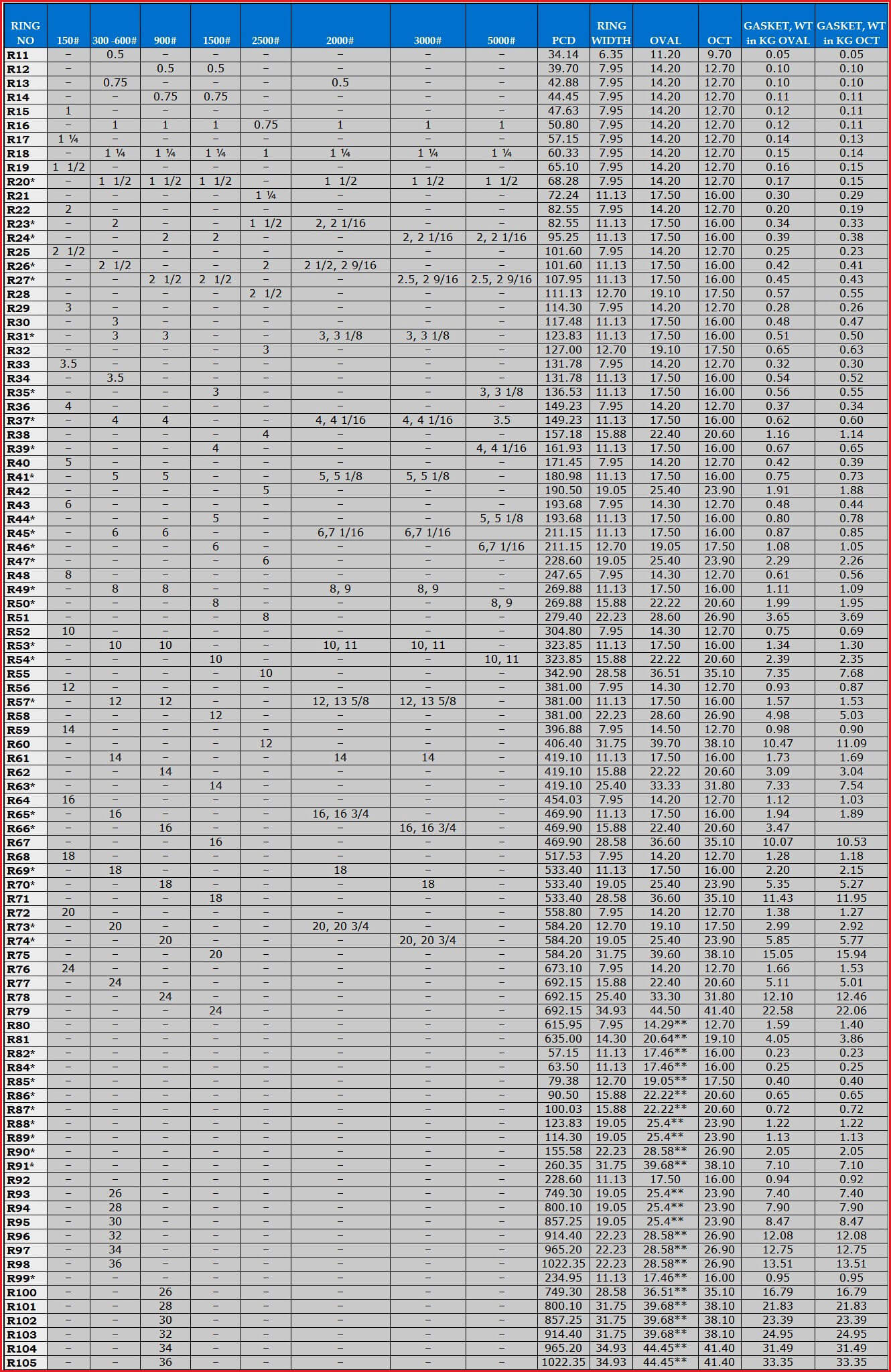

- R Type RTJ Gaskets

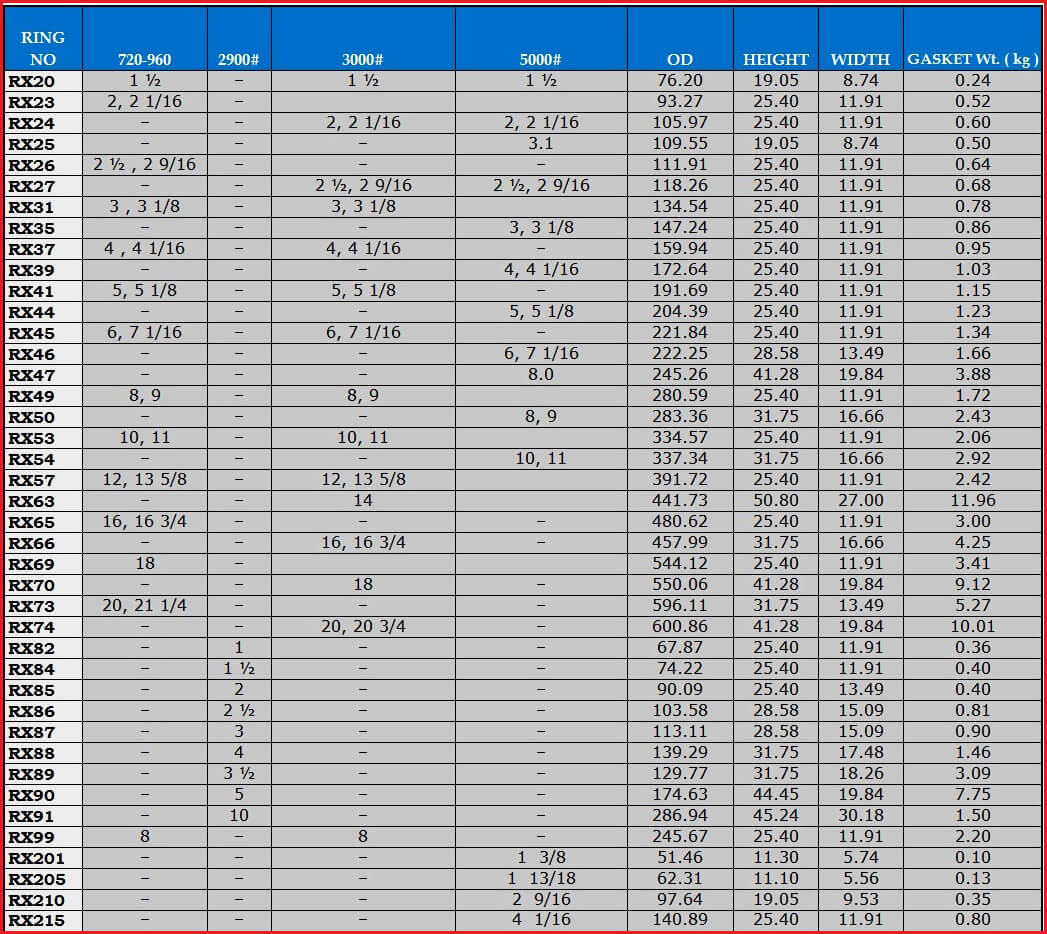

- RX Type RTJ Gaskets

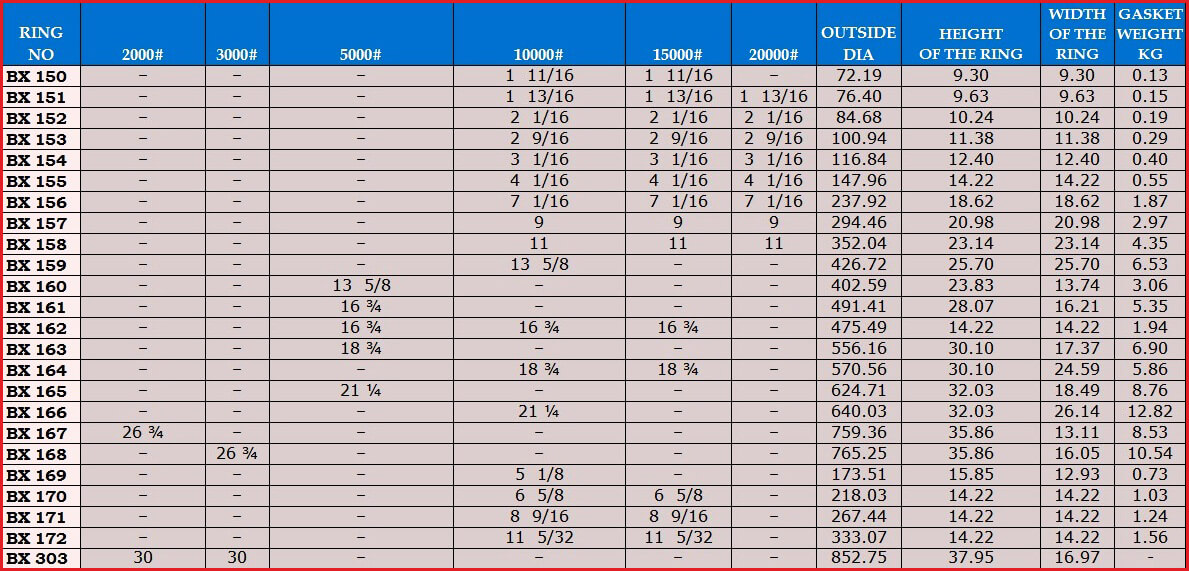

- BX Type RTJ Gaskets

- SRX and SBX RTJ Gaskets

- Specialty RTJ Gaskets

Pipeline Solutions Pvt. Ltd.'s Ring Type Joints Gaskets exceed expectations in high-weight applications, for example, oil and gas investigation and generation. Ring Type Joints Gaskets are additionally utilized on valves and pipework gatherings in refineries and different procedure commercial enterprises.

Accessible in both oval and octagonal profiles, standard style R ring sort joints are produced to meet both API 6A and ASME B16.20 sizes and evaluations. Additionally accessible are Style RX Ring Type Joints Gaskets which empowers on get together.

This sort is intended to fit the same section as a style R in this way making them exchangeable. For high weights, frequently found in sub-ocean wellhead and Christmas tree frameworks, the style BX is utilized. Subsea adaptations of all styles are accessible with weight equalization gaps.

We additionally outline and fabricate uncommon Ring Type Joints Gaskets and bespoke strong metal gaskets for topside and subsea victory preventers. Ring Type Joints Gaskets gaskets can be supplied in an extensive variety of stainless steels, Inconel compounds and other master metals. Coatings accessible incorporate zinc, Xylan and silver.

Metallic Ring Type Joints Gaskets are substantial obligation, high-weight gaskets to a great extent utilized as a part of seaward and inland petrochemical applications. They are accuracy built segments intended to be utilized as a part of conjunction with exactness machined flanges. All our Ring Type Joints Gaskets are fabricated by B16.20 and API 6A.

• The Ring Type Joints Gaskets material is chosen on various grounds basically; compound similarity with the media and the hardness of the flange. The gasket material preferably should be about 30 Brinell not exactly the flange material to guarantee adequate distortion of the gasket without harming the flange confronting.

• Worn, hollowed or eroded flange fixing surfaces can hinder the fixing capacity of Ring Type Joints Gaskets. In such cases, a serrated octagonal RTJ gasket, secured with adaptable graphite or a Maxiflex CR-RJ, can give an interim or crisis arrangement until the flange can be repaired or supplanted.

• The fixing surfaces on the Ring Type Joints Gaskets must be easily completed to 63 Microinches and be free of shocking edges, instrument or babble marks.

We provide RTJ Gaskets that are precision machined, metallic sealing rings. These gaskets are best suited for high pressure and high temperature applications. Specially designed to seal by "initial line contact" or wedging action between the mating flange and the gasket, this range is widely appreciated for unmatched performance.

FEATURES :

Material Chart

| Material | Ring | DIN | DIN | AISI | B.S. | Hardness (max)* | Temp | Density | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (trade name) | identification | specification | material | ASTM | Brinell | Rockwell | [oC ] | [gr/cm3] | ||

| nr. | UNS | HB | B | min | max | |||||

| soft Iron | D | 90 | 56 | -60 | 500 | 7.85 | ||||

| Steel (LCS) | S | 120 | 68 | -40 | 500 | 7.85 | ||||

| ASTM A 182-F5 | F5 | 12CrMo 195 | 1.7362 | A182-F5 | 130 | 72 | -40 | 650 | 7.9 | |

| SS 304 | S 304 | X5CrNi 189 | 1.4301 | 304 | 304S15/16/31 | 160 | 83 | -250 | 550 | 7.9 |

| SS 309 | S 309 | X15CrNiSi 2012 | 1.4828 | 309 | 309S24 | 160 | 83 | -100 | 1000 | 7.9 |

| SS 316 | S 316 | X5CrNiMo 1810 | 1.4401 | 316 | 316S31/33 | 160 | 83 | -100 | 550 | 7.9 |

| SS 316L | S 316L | X2CrNiMo 1810 | 1.4404 | 316L | 316S11/13 | 160 | 83 | -100 | 550 | 7.9 |

| SS 321 | S 321 | X10CrNiTi 189 | 1.4541 | 321 | 321S12/49/87 | 160 | 83 | -250 | 550 | 7.9 |

| SS 347 | S 347 | X10CrNiNb 189 | 1.4550 | 347 | 347S31 | 160 | 83 | -250 | 550 | 7.9 |

| Monel 400* | M400 | NiCu30Fe | 2.4360 | NO4400 | 3072-76NA13 | 130 | 72 | -125 | 600 | 8.8 |

| Inconel 600* | INC -600 | NiCr 15Fe | 2.4816 | NO6600 | 3072 - 76NA14 | 200 | 94 | -100 | 950 | 8.4 |

| Inconel 625 | INC -625 | NO6625 | 200 | 94 | ||||||

| Incoloy 800* | INC -800 | x10NiCrAITi 3220 | 1.4876 | NO8800 | 3072-76NA15 | 200 | 94 | -100 | 850 | 8 |

| Incoloy 825* | INC -825 | NiCr 21Mo | 2.4858 | NO8825 | 3072-76NA16 | 160 | 83 | -100 | 450 | 8.14 |

| Titanium | Ti | Ti 99.8 | 3.7025 | 160 | 83 | -250 | 350 | 4.5 | ||

Dimension Charts

For any Enquiries related to Ring Gaskets, please contact us on:

Email:- pipelineorder@gmail.com / info@pipeline-solutions.in

Contact: +91 22 67431301 / +91 9833671857